The Best Guide To Gable Spandrel Panel

Table of ContentsSome Known Facts About Replacement Double Glazing Panels Prices.The Of Gable Spandrel Panel5 Easy Facts About Gable Spandrel Panel Described5 Easy Facts About Fire Rated Spandrel Panel ExplainedNot known Facts About Replacement Double Glazing Panels PricesInsulated Metal Spandrel Panels Can Be Fun For Everyone

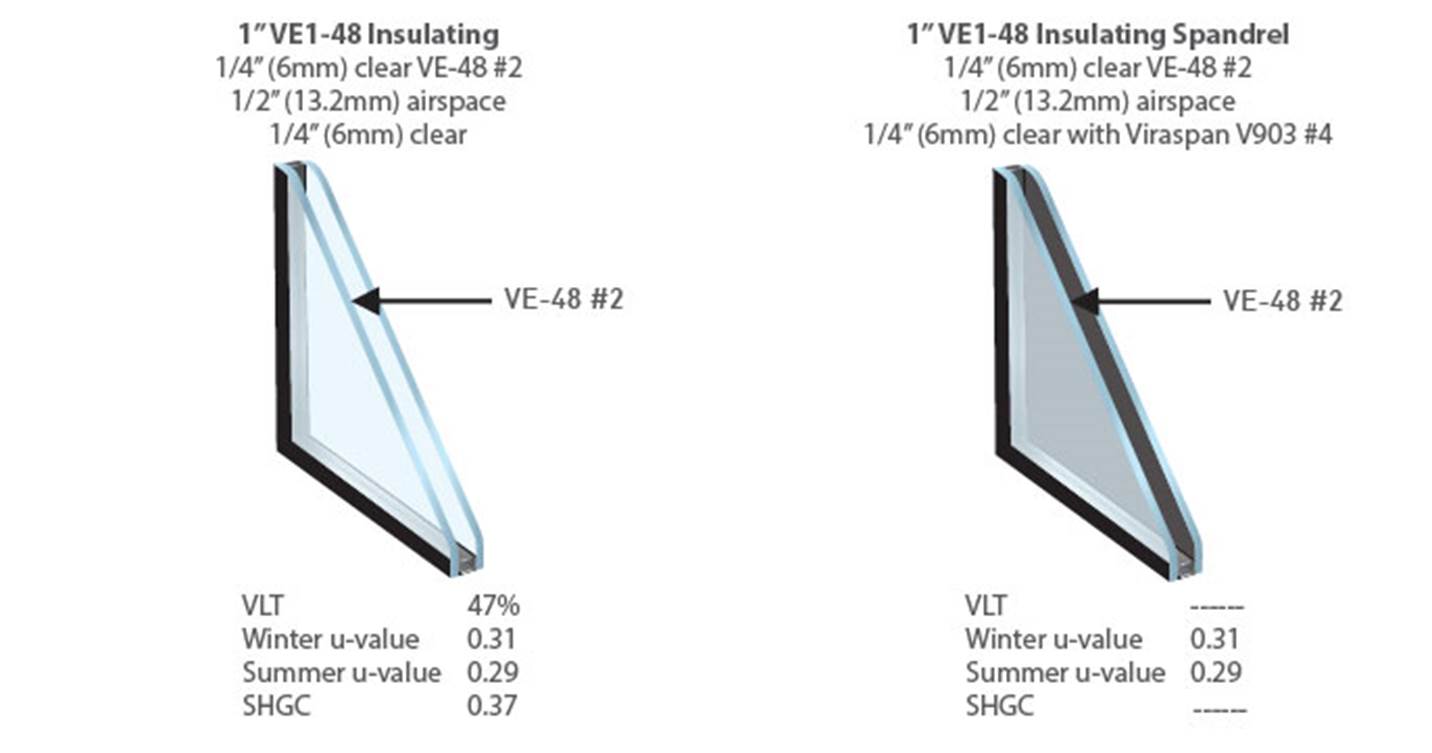

Periodically, there are worries connecting to having way too much unrestrained daylight, in some cases referred to as glow. The difficulty is to pursue the highest possible visible light passage (VT) and also the least expensive solar warm gain coefficient (SHGC) while not protecting against the glass from being as well reflective when viewed from both the exterior and the interior, while regulating glow.The units ought to be totally assembled in a factory as well as shipped to the site for installment on the structure. The units are put on the floors, packed in crates, utilizing the tower crane and also decreased into place utilizing a smaller crane or hoist possessed by the glazing specialist. The mullion measurements have a tendency to be somewhat larger than a stick system because of their open area as compared to television form of a conventional stick drape wall surface area.

Systems can be constructed in a factory while the architectural structure of the building is being constructed. Where stick systems call for numerous actions to put up and also secure the wall surface, unitized walls get here on the site totally constructed enabling the floorings to be closed in quicker (replacement double glazing panels prices). Unitized systems additionally call for less space on site for format hence providing a benefit for metropolitan sites with area restrictions.

Facts About Replacement Double Glazing Panels Cost Uncovered

The interlocking vertical mullions will typically have 2 interlacing legs. One leg will remain in the airplane simply behind the glazing pocket as well as the other at the interior face of the mullions. The interlocking leg in the plane of the glazing pocket will be secured by gaskets and is the key line of protection versus water and also air seepage.

Equipments whose connecting legs lock likewise compromise the capacity of the system to suit activity. Some unitized styles are delicate to small irregularities in the spacing of adjacent components; for instance, if the module joints are somewhat out of resistance, gaskets might not be correctly pressed and also wetness security might experience.

The four-way junction refers to the location where 4 adjacent devices satisfy. This is where field labor need to seal in between surrounding devices to achieve a climate limited wall surface. The interlacing legs of the horizontal mullions are one of the most essential user interface of a unitized system. Water that infiltrates the interlocking vertical mullions drains pipes to the interlocking horizontals that need to collect and divert this water to the exterior.

7 Simple Techniques For Secondary Glazing Panels

These upstanding legs have gaskets that seal against the walls of the lower straight. Some layouts provide one honest leg that provides one line of defense against air as well as water seepage. More robust systems will certainly give two upstanding legs with gaskets on both legs. A splice plate or silicone flashing that is mounted at the top of both surrounding units as they are put up on the building is generally needed.

The stack joint is the straight joint where devices from adjacent floorings satisfy. Placing the pile joint at the sill of the vision glass (generally 30" above the flooring) will lessen the dimension of the vertical mullions. This positioning utilizes the back span of the mullion above the anchoring point at the slab to neutralize the deflection of the mullion listed below the piece (replacement glazing panels).

Define that laboratory examinations are to be performed at an AAMA Accredited Research laboratory center. Field Mock-up: For all drape wall surfaces, supply or customized, require building as well as screening of a field mock-up agent of the wall/window assembly. spandrel glazing metal panel system This is best set up before the release of shop drawings for home window manufacturing, so that there is an opportunity to make design adjustments based upon the examination efficiency of the field mock-up.

Not known Facts About Concrete Spandrel Panel

The details associated with this area of the BEDG on the WBDG were created by committee as well as are meant entirely as a way to highlight basic style and also construction principles just. Appropriate usage as well as application of the concepts showed in these details will certainly vary based upon performance factors to consider and also ecological problems special to every task and also, therefore, do not stand for the final opinion or referral of the author of each area or the committee members in charge of the advancement of the WBDG.

Constant metal sill blinking at the base of the curtain wall shields the wall surface framework below from leak through the drape wall surface. Sill flashing need to have upturned end dams as well as fully secured corners. Intermediate horizontal must be wept to the outside as well as prevent water from draining onto the head of the glazing system listed below.

Some Of Aluminum Spandrel

Gasket elevation should correspond to the drape wall layout pressure. Pressure equalized rainscreen gaskets form a primary weather seal at the face of the unitized vertical stack joint in line with the horizontal rainscreen gasket at the device sill below.

Spandrel glass adapters are used to minimize the deepness of the glazing pocket to fit minimized account of spandrel glass. Spandrel glass adapters ought to be fully bedded in sealer and incorporated with glazing pocket corner seals to stop water leak from polishing pocket to building interior. Device dimension of breeding head and also sill squeezed out profiles enables specified floor to floor deflection at the stack joint.

Intermediate horizontals quit at the face visit the website of the vertical unit jamb participants at each end. Devices are hung from the top or Discover More face of the nearby flooring or building structure making use of mated braces as well as field used screws with a minimum of clearance for accessibility and assembly. All links as well as brackets situated within the devices protected or primary climate seal zones are secured with ideal sealant materials during field installment.

The Replacement Double Glazing Panels Prices Ideas

non-heat-treated) or completely tempered glass to continue to be in position till it can be replaced. Whether heat-strengthened or totally tempered, heat-treated glass items are produced in a similar fashion and also making use of the very same processing devices. The glass is heated to around 650 C (1200 F), then force-cooled to develop surface area and also side compression.

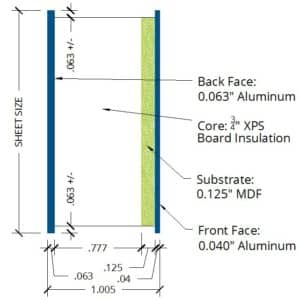

As suggested in Number 1, insulation is commonly used combined with spandrel glass. When the insulation is to be applied directly to the opacified surface of the spandrel glass, it is necessary to collaborate with a glass spandrel fabricator, along with the adhesive as well as insulation providers, to make certain these products work with the opacifying material. fire rated spandrel panel.